High mast lighting is more than a product—it is the backbone of large-area illumination for ports, airports, highways, stadiums, logistics hubs, and city squares. At INBRIT, we treat every high mast not as a single structure of steel, but as a piece of engineering that must stand firm, operate reliably, and remain safe across decades of outdoor service.

Our 25m high mast pole is a prime example of this philosophy.

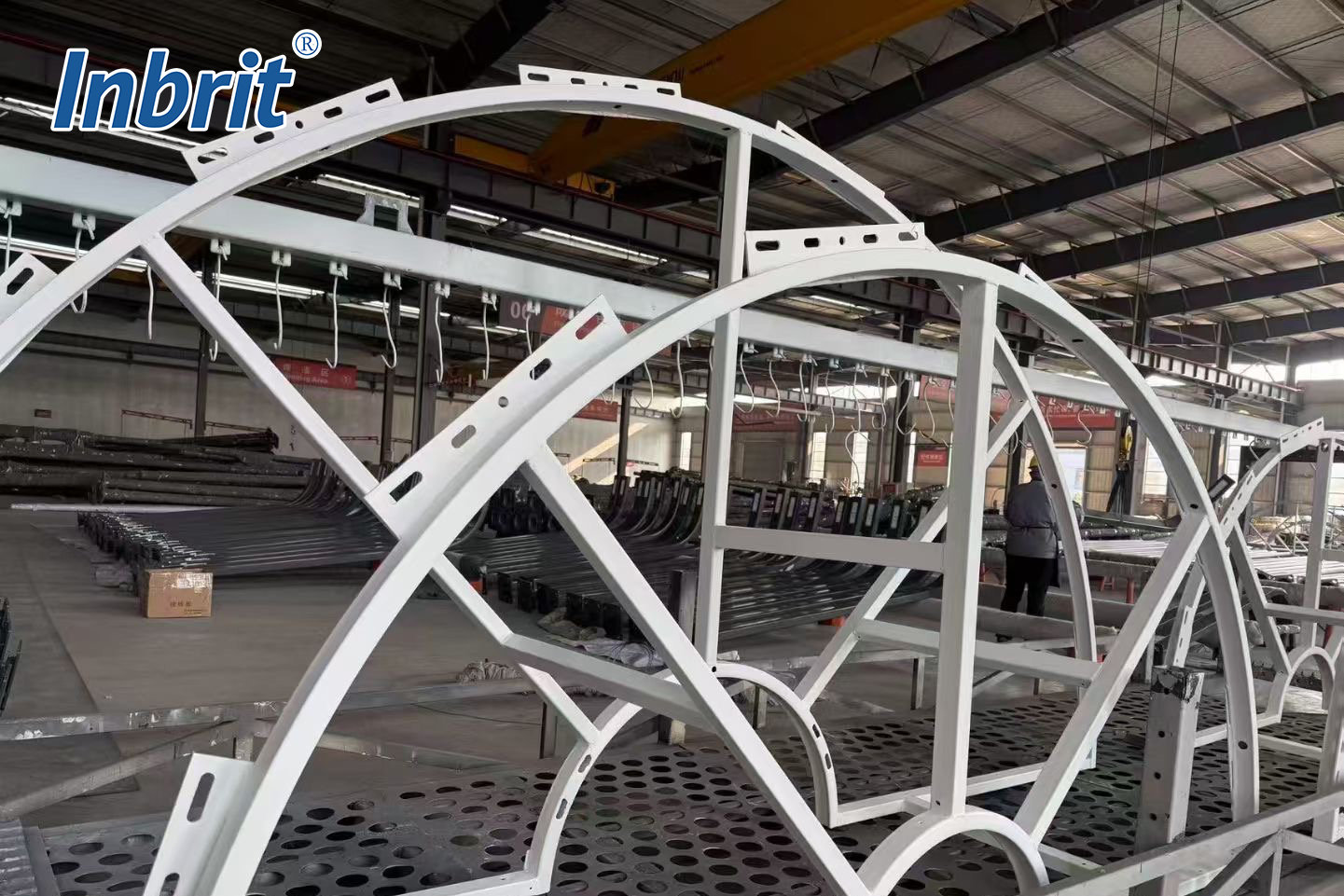

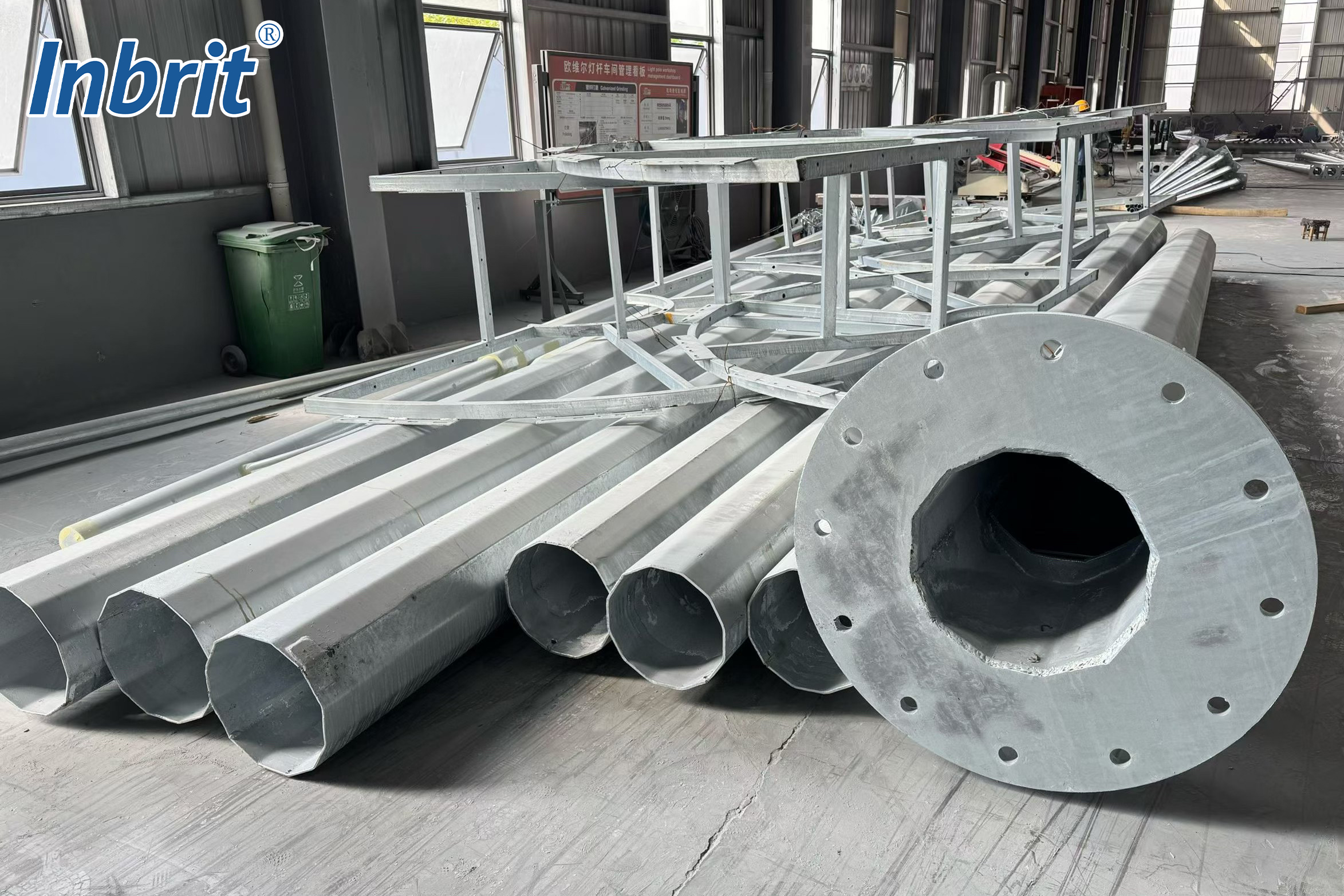

Factory-shot, without filters, the pole stands like a true “giant” in our workshop. Every weld, every cut, and every millimeter of precision reflects our commitment to producing engineering-grade equipment—not showroom samples, but products that can be directly delivered to real-world projects.

1. Robust Structure Designed for Long-Term Reliability

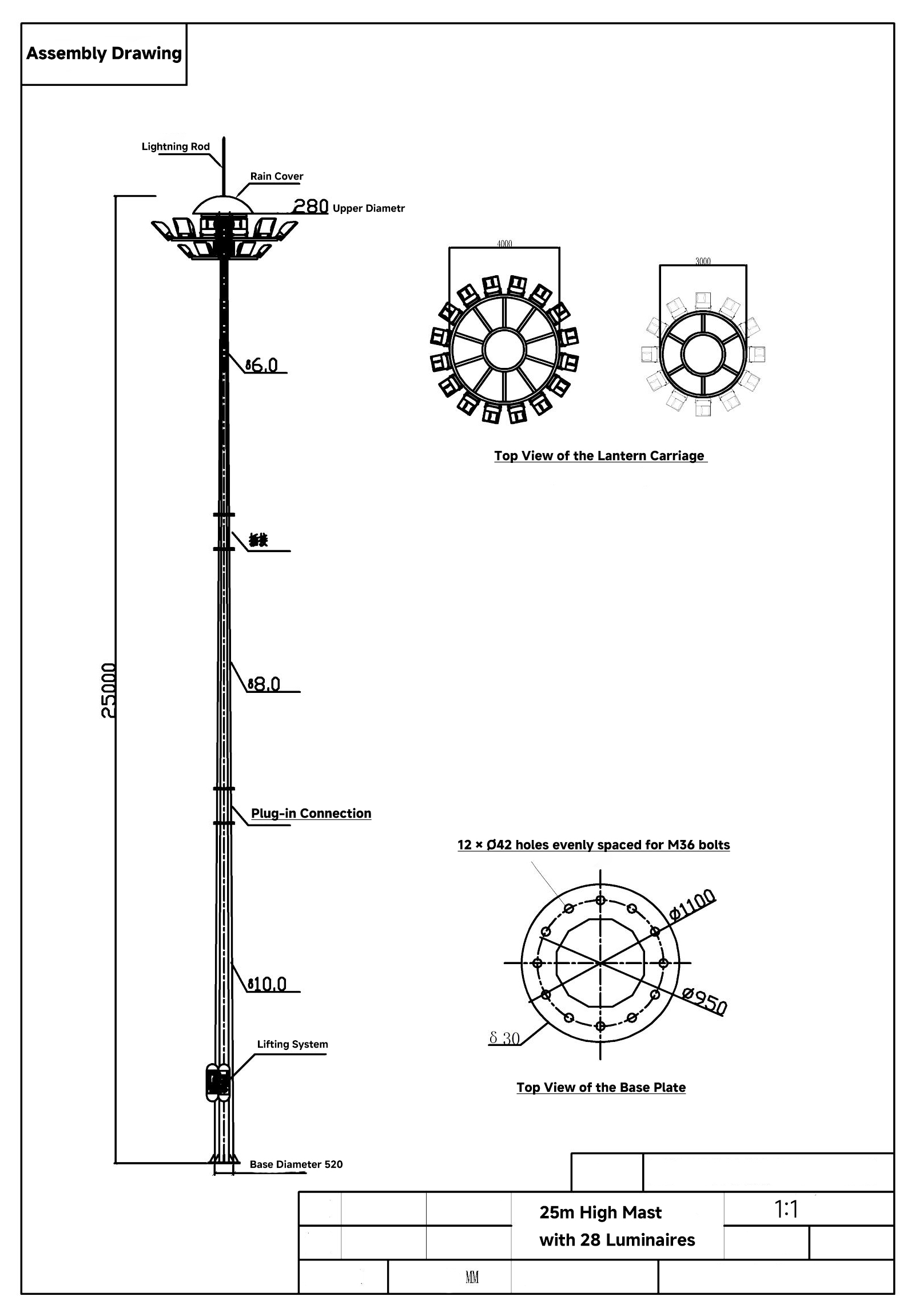

The overall mast is manufactured using high-quality Q355 steel, divided into three sections for ease of transport and installation. The sections from top to bottom have wall thicknesses of 6 mm, 8 mm, and 10 mm, ensuring structural stability while optimizing material usage.

All steel components undergo internal and external hot-dip galvanization with a zinc coating thickness exceeding 86 μm, providing exceptional corrosion resistance. For added durability, the surface is treated with an outdoor-grade polyester powder coating, with a thickness greater than 90 μm. Colors can be customized according to project requirements.

The mast is also equipped with a lightning protection system, ensuring safety in extreme weather conditions. The combination of sectional steel, high-quality Q355 material, and dual anti-corrosion treatment ensures that every INBRIT high mast can withstand wind, vibration, and long-term outdoor exposure.

2. Automatic Lifting System for Efficient Maintenance

To maximize operational convenience and minimize maintenance costs, the mast is equipped with a fully automatic lifting system.

This system combines advanced automation with high reliability, allowing the luminaire ring to be raised and lowered at the push of a button for routine inspections, LED module replacement, or electrical system checks. The mechanism is designed with:

High-strength stainless steel wire ropes

Low-noise, high-torque winch components

Secure multi-point locking structures

Fail-safe descent protection

Smart control interface for remote operation and monitoring

With this fully automated system, routine servicing becomes faster, safer, and more efficient—significantly reducing downtime and labor costs for end users while ensuring precise and consistent operation.

3. Engineering-Grade Details That Define Quality

To meet global engineering standards, each high mast can be customized with:

Lighting Head Options

Ring-type luminaire brackets

Platform-type luminaire brackets

6/8/10/12/16-luminaire configurations

Adjustable angle brackets to maximize ground uniformity

LED Luminaire Options

200W–1000W high-power LED modules

High-efficiency LED chips with up to 170–200 lm/W

IP66/IP67 waterproof protection

Surge protection up to 10kV/20kV

Safety & Electrical Systems

Aviation obstruction light

Lightning protection grounding

Internal cable management

Optional smart control system for dimming and remote monitoring

These details transform the mast from a simple steel pole into a complete lighting solution optimized for large-scale projects.

Assembly Drawing of High Mast Light

4. INBRIT Production Strength: Where Giant Masts Are Born

Every INBRIT high mast is manufactured in our dedicated production facilities equipped with:

Large-size CNC bending & forming machines

Automated submerged arc welding equipment

12–15 m sectional pole production lines

In-house powder coating and surface treatment lines

With an annual production capacity that supports large municipal, airport, and highway projects, INBRIT is structured to meet the global demand for robust, high-quality outdoor lighting systems. Our production process follows strict quality control systems, including:

Raw material inspection

Welding quality NDT testing

Vertical straightness testing

Galvanization thickness measurement

Powder coating inspection

Vibration and wind-resistance assessments

These processes ensure every mast can be safely installed and relied upon for years—even in harsh environments.

5. Packaging and Delivery

Each mast section is carefully packaged using bubble wrap plus black blankets, ensuring protection during transportation. Technical drawings are included with every shipment to assist on-site installation teams.

6. Ready for Global Engineering Projects

Our 25 m, Q355 steel high mast—with sectional wall thicknesses of 6/8/10 mm, >86 μm hot-dip galvanization, outdoor polyester powder coating >90 μm, and semi-automatic lifting system—is more than a product specification. It represents INBRIT’s manufacturing capability and our commitment to durable, project-ready solutions.

Every high mast shipped from our facility is ready for direct installation, meeting international standards such as:

GB/T pole structure standards

ISO9001 quality management

ISO14001 environmental management

CE and RoHS compliance (for luminaires)

INBRIT high mast lighting solutions have been widely used in ports, highways, stadiums, airports, industrial parks, and smart city upgrades across Asia, the Middle East, and Africa.

Conclusion: Built Strong. Built Smart. Built to Last.

INBRIT’s high mast lighting is manufactured with precision, strength, and responsibility.

From Q355 steel and sectional wall thickness design to internal lifting mechanisms, from dual anti-corrosion treatment to customizable powder-coated surfaces, every detail is engineered to provide long-term safety and exceptional performance.

When you choose INBRIT, you choose a partner committed to durability, engineering excellence, and the reliability of large-scale projects.

0086 19352672322